advantage:

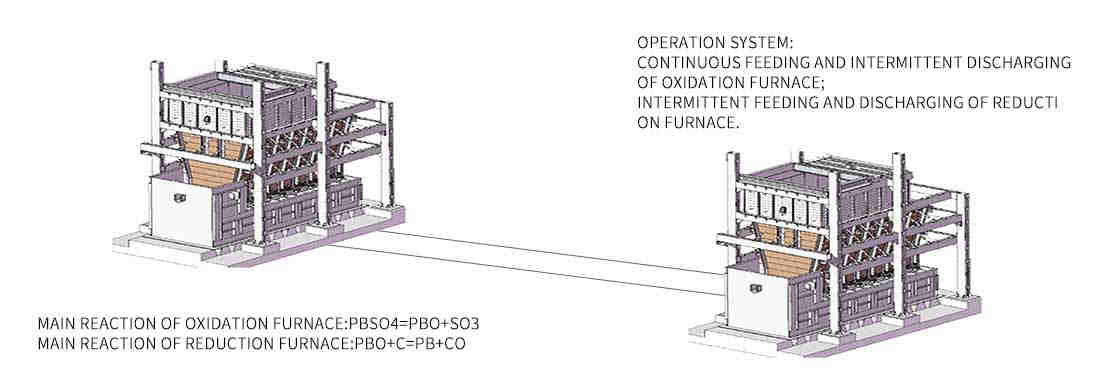

The SO2 concentration in the flue gas of oxidation furnace can be stable At 2.7 ~ 3%, the acid production is more stable.shortcoming:

The investment of the two furnaces, the consumption of fuel, oxygen and labor, has increased the investment and operation cost; The concentration of SO2 in the flue gas of oxidation furnace is low, which still can not meet the requirements of direct acid production, and the acid can be produced only after ionic liquid concentration is also required; Coal is added to the reduction furnace, and the flue gas needs desulfurization. If ionic liquid absorption is adopted, the investment of ionic liquid will be increased.

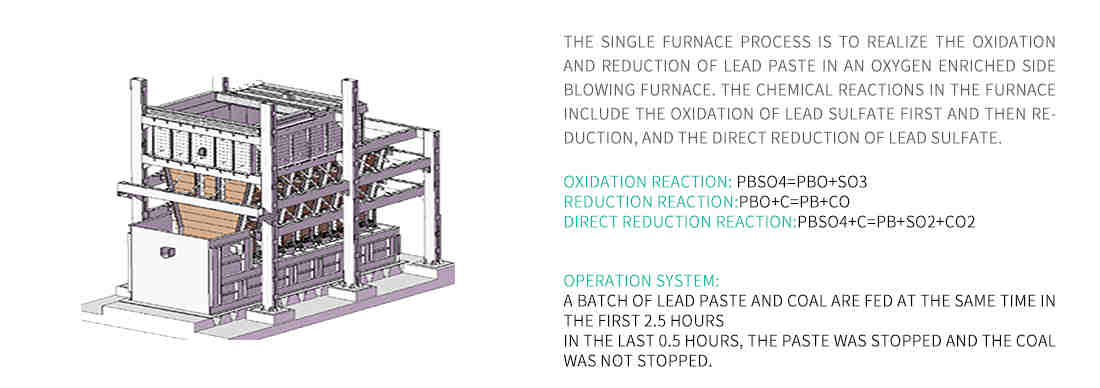

advantage:

The SO2 concentration in the flue gas of oxidation furnace can be stable At 2.7 ~ 3%, the acid production is more stable.shortcoming:

The investment and operation cost of the two furnaces are increased; The concentration of SO2 in the flue gas of oxidation furnace is low, which still can not meet the requirements of direct acid production, and the acid can be produced only after ionic liquid concentration is also required; Coal is added to the reduction furnace, and the flue gas needs desulfurization. If ionic liquid absorption is adopted, the investment of ionic liquid will be increased.RE type lead paste side blowing furnace is composed of hearth, copper water jacket and vertical flue. Using anthracite as reducing agent, anthracite, natural gas or a combination of both can be used as fuel according to the needs of users. The water jacket adopts the form of three-layer copper water jacket, equipped with primary air duct and secondary air duct, and can be equipped with natural gas spray gun according to the needs of users.

WeChat scanning

WeChat scanning

Copyrights©2022 HUNAN RE TECHNOLOGY Co.,Ltd. Sitemap Iicense 湘ICP备2022006975号-2

Technical Support:Compete to win